Universal Testing Machines

The materials testing machines of the smarTens (single or 2-spindle machine up to 30 kN) or proTens (2-spindle machine up to 250 kN) series are suitable for many different applications and uses for demanding testing tasks in the field of quality control as well as for R&D. The extensive range of accessories and the modular design allow a wide variety of expansion options, even at a later date or if the machine configuration has to grow with the tasks placed on it. The proTens series in particular is available in various test chamber dimensions (height, width) and can therefore be optimally configured for your testing task.

Universal Testing Machines series „smarTens 2.5 IS“

Single ball screw drive with solid state servo and motor controls for loads upto 2.5 kN.

High-precision single-column testing machine for strength tests in the lower load range. Developed for the most varied testing application in the laboratory, in production or in research and development. Due to the large number of available test programmes, almost all conceivable tests, such as tensile, compression or bending tests as well as pull-off, peel or shear strength tests are possible. The large application range of this machine allows tests in the load range up to 2.5 kN on plastics, elastomers, paper, wires, cords, foams, but also tests on finished parts. In combination with our powerful Windows® software, simple standard tests as well as user-specific tests can be caried out in a user-friendly and reliable manner.

Features / Equipment:

- Load range max. 2.5 kN

- Available in 3 different test area heights

- Innovative brushless motor without gear drive for long life

- Minimised noise emissions due to low motor speed and optimised frequency range

- Highly accurate force measurement: Class 1 from 0.1 % to 100 % nominal force according to DIN EN ISO 7500-1 or ASTM E4 (optional class 0.5)

- Testing speed from 0.0015 to 1200 mm/min

- Designed for standing or sitting work at the UTM

- Large machine base plate for mounting accessories and storing tools or samples

- User-friendly software

Universal Testing Machines series „smarTens 5/10 ID“

Two-spindle universal testing machine for a load range up to 5 or 10 kN

The two-spindle universal testing machine series smarTens ID has two backlash-free ball screws in H-frame design with spindle protection and innovative brushless drive motor. The newly developed testing machine is available in two different test testing area heights and can thus be optimally adapted to individual requirements. These models (table machines) are equipped with modern microprocessor technology and a universal testing software which allows strength tests on metals, non-ferrous materials, plastics, elastomers, wires, cords or foams. This testing machine series is mainly designed for standardised testing tasks according to national or international standards as well as for use in quality control.

Features / Equipment:

- Load range 5kN and 10 kN

- Available in 2 different test area heights

- innovative brushless drive without gear

- reduced noise pollution due to low motor speed and optimised frequency range

- freely selectable control of crosshead travel, force or elongation

- highly accurate force measurement by means of DMS load cell

- compact workplace design

- designed for standing as well as sitting activities due to very flat lower crossbar and lateral arrangement of the electronics

- Large machine base plate for the adaptation of accessories and the storage of tools or samples

- Variable speed upto 1200 mm/min.

Universal Testing Machines series „smarTens 20/30“

Twin ball screw drive universal testing machine for loads up to 20 or 30 kN

The smarTens 20 / 30 kN materials testing machines were designed for standard and routine tests. These universal testing machines are used in quality assurance and are characterised by a particularly attractive price/performance ratio. The smarTens 20/30 is suitable for tensile, compression, peel and bending tests on different materials. In combination with the ergonomic design and the new brushless drive concept, a safe and fast measurement with easiest operation is guaranteed both in rough production environments and in sterile labo

Features / Equipment:

- Load range max. 30 kN

- Innovative brushless drive without gears

- reduced noise due to low motor speed and optimised frequency range

- freely selectable control of crosshead travel, force or elongation

- high-precision force measurement by strain gauge force transducer

- designed for standing (with optional substructure table) and seated work

- ersatile adaptation of accessories and additional force transducers

- Variable speed up to 400 mm/min.

Universal testing machines series „proTens“

Twin ball screw drive with solid state servo and motor controls for loads up to 250 kN

These universal tensile tester series "proTens" (table standing) incorporate an advanced microprocessor technology. In combination with our user friendly software we provide an extremely efficient, reliable approach to any materials testing need. Well-known for their versatile performance and rugged mechanical design, these machines are designed to accommodate a wide range of applications (e. g. quality and production control, R & D and test labs) to be able to meet the most demanding test requirements. It is designed to perform a variety of test procedures, including compression, tension, shear, peel and flex. The large application range permits testing of metals, plastics, elastomers, foam materials, wood, ropes, cords, wires as well as strength tests (tensile and compression tests) at finished parts.

Features / Equipment:

- Force range up to 250 kN

- Two different type of motor (300 W or 900 W)

- User-friendly software

- Cross head guidance system

- Quick-disconnect load cell and fixture system

- Adjustable overload stop

- Load measurement accuracy: Class 1 from 0,1 % to 100% of rated capacity acc. DIN EN ISO 7500-1 and ASTM E4 (optionally Class 0,5) Variable speed upto 2000 mm/min.

- Different test space widths (+ 190 / +330 / +620 mm) or test space heights (+250 / +500) are available for each machine type and can thus be adapted to almost all testing tasks or component geometries

- Expandable with temperature test chambers

RMCi - Handpanel

Manual operation for all machines of the smarTens and proTens series with PC.

RMCi 6:

- Crosshead movement

- Stop, Return

- Display of current force and displacement values

- Mounting bracket for mounting on column profile Load frame 1+2, right side of machine

- Remote unit with 15 keys, DigiPoti and display and M12 interface

- OLED monochrom display with 128p x 64p and status LEDs

- Internal EDCi interface and protocol – supply voltag +24 VDC, RS485 communication

- Magnetic foil for easy fixation to testing machine chassis for comfortable use

RMCi 7:

with EMERGENCY STOP, Function - necessary in safety door operation

- Crosshead movement

- Test start, stop, return

- Emergency stop button

- Opening and closing of extensometer arms and fixtures

- Display of current force and displacement values, storage and output of test results

- Parameterization of simple tensile compression and bending tests

- Mounting bracket for mounting on column profile, Load frame 1+2, right machine side

- OLED-Monochrom-Display with 128p x 64p und status-LEDs

- Internal EDCi interface und protocol – voltage supply +24 VDC, RS485 communication

- Magnet foil for easy fixation at the testing system for comfortable use

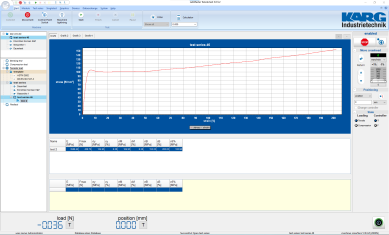

Software

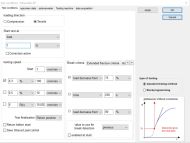

Our material testing software has been developed in a modular design and consists of a comprehensive basic software. This allows simple but also complex testing tasks to be configured in a standard-compliant or customer-specific manner. A large number of templates or pre-configured test parameter sets are available for standardised and standard-compliant test tasks. In addition and for the individual creation of test cycles, a freely programmable software (block program creation) with the following features is available:

- Free programming of a sequence control for static or dynamic tests

- Individual definition of test parameters including calculation / display of test results (force, displacement, strain or any other measured values such as temperature, weight, etc.)

- All test results can be converted with arithmetic formulas.

The integrated test wizard can be used to configure the test sequence individually, so that the user only has to operate the necessary input windows, receives supporting information and can work through his tasks purposefully. Our software works under Microsoft Windows® and guarantees „Microsoft Office® compatibility", i.e. all results can be exported to other applications such as Access®, Excel®, ASCII-file or other SQL applications. The integrated report generator allows individual report generation including graphical display in single or series mode. The software is available in different languages.

Karg Industrietechnik: Competence

in materials testing

Do you have questions about our products and services that are not answered on this website? We have the answers and solutions!

Contact now