Notching Machines

For the precise notching of a wide variety of shapes and geometries in one sample.

Product catalog

Notching Machines (PDF)

Manual and motorized Notching Machines type MAK and MOK

These linear notching machines (manual and motorized version) are developed to prepare, rapidly and accurately, V- or U- notched specimens for impact resilience determinations according to Charpy, Izod and Tensile Impact (ASTM, ISO, DIN or others). Therefore these machines are used in conjunction with impact pendulums. Interchangeable notching knives are designed with a constant profile to notch the specimens with the correct angle and radius as prescribed by the standards. The machines are fitted with two separate motion systems: one to move the specimens and the other to move the knife; the motorized machine has got a frequency controller for an adjustable speed.

Features / Equipment MAK:

- Robust and stable instrument

- Manual actuation by means of crank mechanism

- Precise and stable knife guiding

- Knife tolerances better than 0.01 mm

- Maximum clamping height: 30 mm

- Frictionless and clearance free bearings at loader guiding warranty a very precise and reproducible notch

- Optional: device for dynstat specimen

- Optional: device / adapter for fracture mechanics

- Optional: razor notch

Features / Equipment MOK:

- Robust and stable instrument

- Motorized knife movement

- Knife velocity adjustable by means of a frequency controller

- Plexiglas protection cover with integrated safety switch

- Maximum clamping height: 30 mm

- Optional: device for dynstat specimen

- Optional: device / adapter for fracture mechanics

- Optional: razor notch

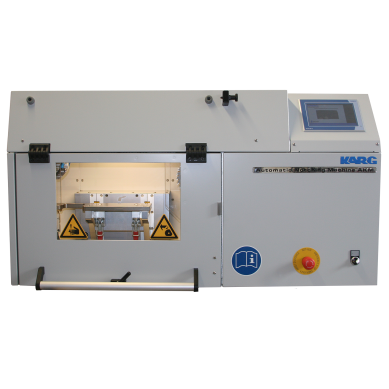

Automatic Notching Machine type AKM

This linear automatic notching machine is developed to prepare, rapidly and accurately, V-notched specimens for impact resilience determinations according to Charpy, Izod and Tensile Impact (ASTM, ISO, DIN or others). As an option, the machine can be equipped with a saw, which permits to separate the shoulders of the multipurpose test specimen. Interchangeable notching knives are designed with a constant profile to notch the specimen with the correct angle and radius as prescribed by the standards. The machines are fitted with two separate motion systems: one to move the specimens (z-Axis) and the other to move the knife and the saw (x-Axis). To ensure the greatest possible flexibility, the cutting and notching feed speed as well as the sawing rotating speed are adjustable in a wide range. A special cooling system ensures that even sensitive materials can be processed with the required precision. A new sealing system ensures that even abrasive or glass fiber-reinforced materials can be processed.

The user interface, a 7" touch screen, allows the programming of the notching or sawing cycles a simple and fast way. Repetitive processing cycles can be stored and are available when needed immediately.

Features / Equipment:

- Robust and stable instrument

- Precise guided movement

- Adjustable knife speed

- Adjustable saw rotating speed

- Plexiglas protection cover with integrated safety switch

- Dual knife and saw cooling

- 7" Touch screen, color

- Clear and easy to use user interface

- Programmable notching and sawing cycles

Karg Industrietechnik: Competence

in materials testing

Do you have questions about our products and services that are not answered on this website? We have the answers and solutions!

Contact now